28 August 2020

Allegations related to environmental and social issues in Halcyon Agri’s Cameroon rubber plantations attracted unwelcome headlines until they were addressed through its Corrie MacColl subsidiary. flow´s Clarissa Dann reports on how sustainable finance is helping the firm set industry standards in rubber

“Rubber is a critical raw material that the world’s mobility relies on – without rubber the world comes to a stop,” declares Ryan Wiener, Global Head of Strategic Marketing at UK natural rubber producer Corrie MacColl. Founded in 1780, the London-based company is now a subsidiary of Singapore-headquartered Halcyon Agri and focussed on the medical and other specialty product sector.

Nothing looks set to entirely replace rubber anytime soon. We see its uniqueness where there are high levels of wear and heat resistance such as in tyres; and although these have man-made components, there is always that irreplaceable natural rubber component in the mix. In addition, the latex harvested from trees is reduced to a rubber solution to make medical equipment such as latex gloves.

Natural rubber is extracted in its raw milky latex form from the trunk of a tree species called Hevea Brasiliensis, which is found in tropical climates. Overall, around 75% of global supplies of natural rubber goes towards the production of tyres, everything else gets the remaining 25%. In that 25%, explains Wiener, is an estimated 40,000 products from natural rubber − anything from condoms to dog toys. Corrie MacColl is focussed on this non-tyre sector and the bulk of Corrie MacColl’s rubber is used in producing medical equipment such as medical gloves, tubing, catheters and condoms, and other specialty products such as adhesives and industrial anti-vibration products. “Our future projected plantation 82,000 tonne output could be used to manufacture 55 billion condoms − or 12 billion medical gloves − each year,” he smiles.

Approximately 70% of global production comes from plantations in Thailand, Indonesia and Malaysia, but the industry has come under considerable scrutiny as a result of its unsustainable cultivation practices.

Part of the reason lies in how rubber is bought and sold on the open market, where pricing is determined on futures markets in China, Tokyo and Singapore. This, explains Halcyon on its website, “represents the views of macro and quant traders, and much less the domain specific knowledge of informed natural rubber market sellers and buyers”.

This volatile trading environment does not encourage sustainable behaviour. “Ninety percent of production is by smallholder farmers who at high prices cause mass deforestation − three million hectares in five years, equivalent to the size of Belgium − by cutting down forests to make way for the planting of more rubber trees. It takes seven years for the trees to grow only for supply to outweigh demand resulting in six million smallholders earning well below their national minimum wage,” explains Wiener.

Changing rubber

On 26 June 2020, the global environmental campaign organisation Mighty Earth’s CEO Glenn Hurowitz sent a letter to European Commission President Ursula von der Leyen on the need to ensure environmental and human rights conditions attached to all EU bailouts and Covid-19 recovery support.

“The tyre and automotive industries are the largest market for natural rubber,” says Hurowitz. “Between 2003 and 2014, the rubber industry tore down 75,000 square kilometres of tropical forest, an area the size of Ireland. This deforestation was responsible for an estimated 3.75 gigatons of pollution during that time, comparable to the amount produced by Europe in a year.” He continues, “While low rubber prices in the last few years have reduced incentives for deforestation and land-grabbing, increased commodity prices in the absence of strong conservation policies would create new incentives for aggressive deforestation”.1

In other words, the message from the NGO was that support given in times of Covid-19 for industries using natural rubber should come with some firm environment and human rights strings attached and that the bailouts are an opportunity to change unsustainable behaviour.

This article however, takes a closer look at another part of the world – Cameroon – where Halcyon Agri Corporation through Corrie MacColl has embarked on an intense sustainability programme partnering with international and local NGOs such as Mighty Earth, as well as Rainforest Alliance, APED, APIFED and Proforest, to transform the natural rubber supply chain.

Turning point

When Wiener joined Halcyon six years ago, the remit was to deliver change. “This was something I saw as very important,” he reflects. He continues, “I was put into the strategy department and we set off on trying to change the way rubber was produced. At that point in time Halcyon managed 14 factories based around South-East Asia – we only engaged in the downstream processing side and set about creating the heightened processing standard we called HEVEAPRO.”

"Sustainability is built from the bottom-up"

Corrie MacColl was established to manage Halcyon’s plantations, and the distribution of product to the medical industry and other specialised rubber product segments. The Corrie MacColl Group’s Cameroon plantation (CMCP) on the West Coast of Africa comprises the Hévécam and SudCam plantations, and taken as one, is the largest commercial rubber plantation in the world.

Hévécam began in 1975 as a Cameroon state-owned enterprise and at that time, roughly 40,000 hectares (ha) of what was previously rainforest was expropriated from indigenous people and other forest-dependent communities in order to make way for rubber plantations. In 2012, the previous management secured an 11,000-hectare extension for Hévécam from the government of Cameroon, and around the same time acquired another concession of approximately 45,000ha bringing the total size of CMCP’s area to around 100,000 hectares.2 It did not come under control of its current owner, Halcyon, until the end of 2016.

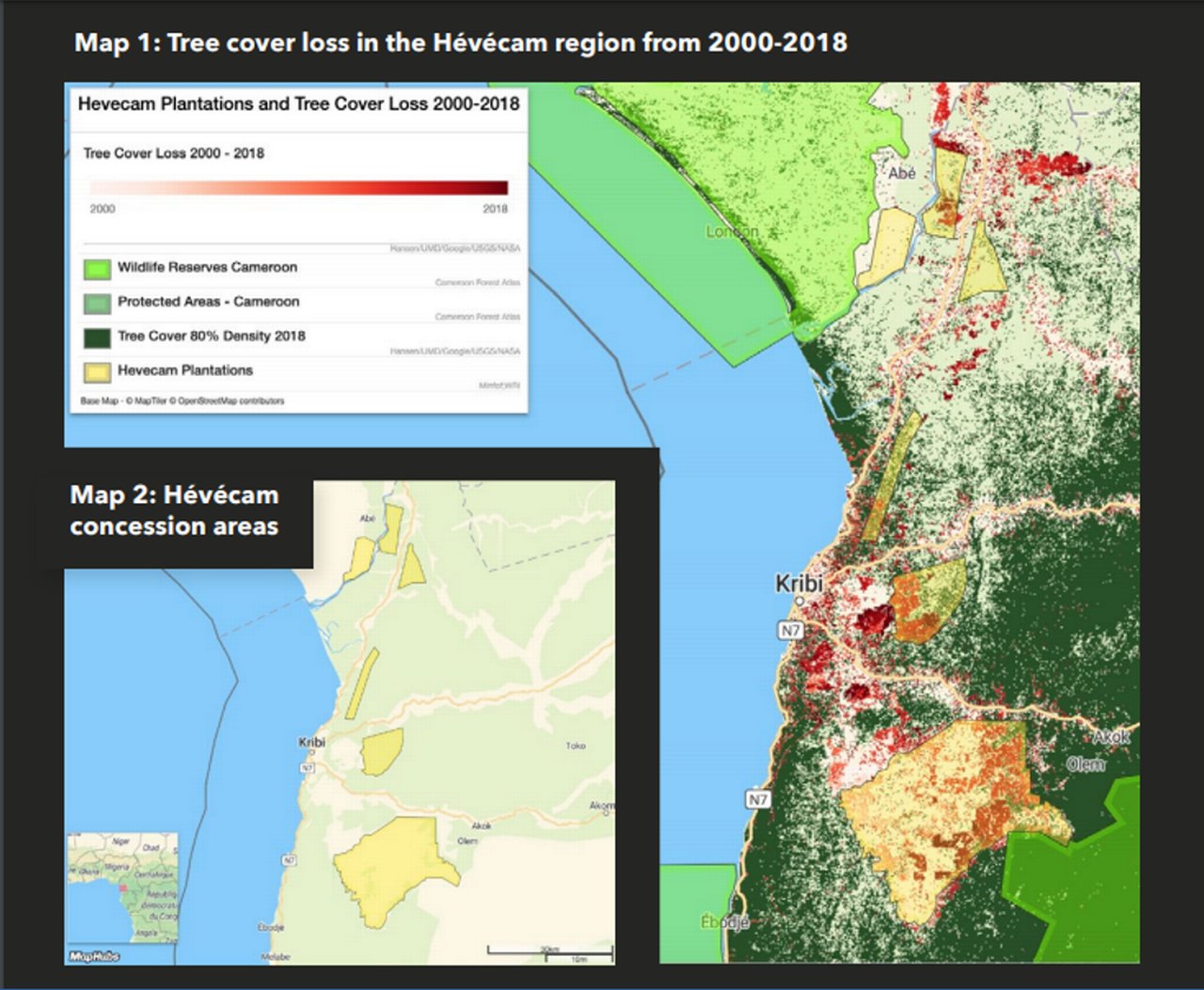

Figure 1: Tree cover loss in the Hévécam region 2000-2018

Source: Mighty Earth (see Note 2)

The scale of CMCP makes the plantation systemically important to Cameroon. In total, says Wiener, the land now within its control amounts to 100,000 hectares – approximately one-and-a-half times the size of Singapore. Around 40,000 residents – of whom more than 15,000 are children under 18 – form part of the wider community for the plantation’s 7,000 workers. This includes 28 villages, 58 government schools and two hospitals, along with various market places, recreation and sports centres. “In truth, Corrie MacColl is Mayor to a sizeable town,” he reflects.

Nurturing the young rubber plants in Cameroon (source: Corrie MacColl)

Rock bottom

From 2018 to 2019 several NGOs published highly critical reports on sustainability standards, which included a number of allegations regarding environmental and social issues in the Cameroon plantations, including deforestation and habitat destruction; encroachment into nature reserves; degradation of watercourses; damage to dwellings and cultural assets of local communities, including indigenous people; involuntary resettlement of people; and poor stakeholder engagement (see Figure 1). In the spirit of transparency, Halcyon Agri has published these reports on its website, along with its responses to each claim, many of which relate to legacy issues that were inherited by Halcyon when it acquired the businesses in Cameroon.

The incoming new management could see from their rubber processing expertise, “the need for significant investment and a management restructure at the HévéCam factory”. An audit applying their third-party certified HeveaPro standards was conducted in January 2017, and the factory scored “an unimpressive 60%”. Fast-forward after a year of investment and a management shuffle, “the factory returned an impressive 92.5%” and was awarded the accolade of Halcyon Group’s “most improved’ factory for that year.

Meanwhile, the true scale of the environmental and social damage caused by the expansion of the plantations had become apparent. “We found that the studies and subsequent management plans run by the previous management were outdated and not up to international standards. This meant that land clearing was adversely affecting critical forest ecosystems while also displacing local and indigenous communities,” recalls Wiener.

Stop, assess, partner and re-align

Preparing the plantation in Cameroon (source: Corrie MacColl)

In December 2018, Halcyon management ordered the immediate cessation of all clearing and felling activities, contracts with external contractors were cancelled, and the planned plantation expansion stopped.3 This lead to a permanent ‘No Deforestation’ commitment, which was added to the company’s Sustainable Natural Rubber Supply Chain Policy – a first for the rubber industry, and a commitment made by the entire Halcyon Group.4

“We launched an in-depth investigation into the legacy issues as CMCP looked to re-build from the bottom, up. We aligned ourselves with local and international experts from Civil Society, working hard to earn trust and communicate our desire for real change, rather than be just another greenwashing organisation,” says Wiener.

“As a first step, we commissioned a thorough gap analysis of the environmental and social impact assessments (ESIA) by the international non-profit agency Proforest, and we together developed an environmental management plan (EMP). On top of environmental matters, we also had to gain the trust of local communities and reassure them that our plantations would cause them no further harm,” he explains

Together with Mighty Earth and local NGOs APED and APIFED, the team conducted an extensive community engagement in its Hévécam and Sudcam surrounding communities. After months of face-to-face meetings with local and indigenous people and their nominated leaders, a thorough grievance list was set up and this has now been adapted into a Social Action Plan.

Recognising the need for full transparency and independent oversight, the team and its partners established the independent Cameroon Sustainability Council. Members today include representatives of local and indigenous communities, federal and local-level government officials, international and local NGOs. At present, the Council is reviewing different proposals on how to best manage the 25,000 hectares of their land selected to be protected forest, and how to provide the rights of the forest to the communities.

Expansion beyond borders

The commitment to stop developing could have resulted in an economic hit to the company, which was how it came to develop the Cameroon Outgrower Programme. Not only does it source more rubber, but the programme aims to bring about more socio-economic benefits without an environmental cost by targeting 13,000 smallholders.

“Using satellite imagery, we are able to uphold our No Deforestation commitment by selecting smallholders who were already in possession of degraded or fallow land before the December 2018 cut-off date – in total 27,000 hectares,” explains Wiener. This is how it works:

- Each Outgrower candidate must pass a sustainability assessment and an onboarding process co-developed with Proforest.

- Successful applicants are then provided with the financing, tools and training to develop an integrated farming model with rubber intercropped with fruit, nuts and vegetables, combined with livestock of pigs and chickens.

- The food crops and livestock provide food security for the families; and

- CMCP provides income through the guaranteed purchase of future rubber output when it can be harvested seven years later.

Traceability of the supply chain is key to ensure that no environmental or social harm is caused, says Wiener. “Our strict on-boarding process for our Outgrower Programme means that our rubber is 100% traceable – we are able to map and trace all of our raw material. “

He continues, “CMCP will forever remain low-density planted with 30,000 hectares rubber plantation, 5,000 hectares infrastructure and 65,000 hectares left untouched or protected.”

Thanks to advanced planting technology, there is, he reassures, “a compelling growth story for the plantation”. The company estimates that 4.5 million mature trees will produce 19,000 tonnes of rubber in 2020, growing to 15.5 million mature trees producing 82,000 tonnes in 2030, with the Outgrower Programme taken into account.

Sustainability-linked lending

Sustainability-linked loan facilities aim to facilitate and support environmentally and socially sustainable economic activities and growth. However, the actual use of proceeds in relation to a facility of this kind is not a determinant in this categorisation and, in most instances, it will be used for general corporate purposes.

The proceeds have to be consistent with each of the borrowers’ corporate values and core sustainability strategy aligned with the Loan Market Association and the Asia Pacific Loan Market Association’s Sustainability Linked Loan Principles.5

On 25 July 2020, Deutsche Bank and Halcyon Corporation announced a US$25m sustainability-linked loan facility with a three-year tenor, and an accordion feature to upsize the facility to US$75m, to Corrie MacColl, to finance the company’s capex investments for its rubber plantations in Cameroon and Malaysia. What does “sustainability-linked” mean? It’s basically an agreed set of key performance indicators written into the financing contract.

It was important, said Wiener, “to show this was being done properly, that the lender and borrower were checking all the boxes”. Environmental Resources Management (Singapore) Pte Ltd (ERM) was appointed by the Singapore branch of Deutsche Bank AG “to undertake an environmental and social governance (ESG) due diligence review” of Halcyon and to set a series of ESG KPIs to be applied to what would be the sustainable financing facility.

Once Covid-19 had closed borders, it was impossible for ERM to visit the plantations, so other means of providing full transparency were found such as video conferencing interviews and detailed reporting. Wiener believes it was quite an achievement for all three parties to arrive at such a thorough report and meaningful set of KPIs given the circumstances. “They understood where our operations are, and how we treat standards; unfortunately though, currently there is no set of industry-wide sustainability standards for rubber. Benchmarking must have been tough, but using their experience and expertise, they had to judge for themselves – and I believe they were pleasantly surprised.”

Halcyon has been very transparent in its management of sustainability issues

ERM confirms, “Halcyon has been very transparent in its management of sustainability issues by publishing its policies, dialogue with NGOs and other grievances, independent audit reports and other, related materials on its website. The company was rated as the second most transparent natural rubber producing company globally under the SPOTT (Sustainability Policy Transparency Toolkit) programme (www.spott.org), and there has been good improvement in scores in the HeveaPRO assessments in its Hévécam factory in Cameroon.”

During the KPI recommendation stage, the criteria for KPIs were that they had to be “a suitably meaningful, measurable and core to the borrower’s business – and externally verifiable”. The due diligence process had, said ERM “helped us to determine where the company could enhance its performance and recommend the relevant SPTs to be achieved within this facility”.

Halcyon KPIs

A detail set of KPIs were written into the Deutsche Bank loan agreement setting out targets and reporting requirements. These are summarised below with additional explanation from Wiener.

Land acquisition, community relations and cultural heritage

“This is social engagement. Prior to the loan we engaged local and international NGOs, went out into the surrounding indigenous communities – into the forest - and conducted a thorough social community engagement, noting every grievance and opportunity to assist them. We built the relationships which weren’t held before Halcyon assumed management. We created social action plans. The KPI is about making sure these action plans continue to be implemented.”

Zero deforestation

“This is hugely important. This is a first for the industry and core metric in our Sustainability Policy- a group-wide zero deforestation commitment. This KPI is to establish a monitoring tool so we can report our adherence.”

High Conservation Value (HCV) Area

“This follows from the no-deforestation commitment and specifies areas that require proper management- areas we are protecting.”

Compliance

“This relates to any potential future grievances received, and that we need to address them in a timely manner.”

Forestry Stewardship Certification (FSC)

“Although a wood certification standard and not implemented widely in rubber, Halcyon is going for this certification and if successful will be one of the first producers to achieve this.”

Outgrower programme

“We have certain targets to meet in the implementation of the Cameroon Outgrower Programme.”

Chemical use

“To accelerate our chemical reduction programme across all plantations.”

EcoVADIS and SPOTT HeveaPRO and Latex PRO Certification Health and Safety Workplace fatalities Environmental and Social Impact Assessment (ESIA) of Plantations Resource Efficiency – Water & Energy

“To maintain or better our audit scores under both EcoVadis and SPOTT assessments.6

“These are the factory level standards created internally by Halcyon – HeveaPRO for dry rubber and LatexPRO for wet rubber. They cover quality, environment, health and safety, corporate and social responsibility, and supply chain security and are certified by testing solutions provider TÜV SÜD.7

“This includes the requirement to not only conduct health and safety training, including defensive driving training, for all the employees and contractors within the Cameroonian operations, but to produce records of this having taken place.”

“Again, the KPI is not just about ensuring there are no fatalities across the operations but documentary evidence to prove it.”

“An ESIA assesses the social and environmental impact your operations will have on the area you operate within. Based on the findings, an Environmental and Social Management Plan (ESMP) is developed which is the guideline for your operations of which needs to be followed. This process was conducted by international NGO Proforest, and this KPI relates to the reporting of this.

“Maintaining and improving our resource efficiency within our operations.”

Towards mandatory rubber standards

Deutsche Bank has shown their support in the time of our transformation”, not just once we’ve reached the goal

“There is still plenty to do − we are only at the beginning of a long road to a truly sustainable rubber. This is why our partnership with DB and the opportunity of this loan is so important. Deutsche Bank has shown their support in the time of our transformation, not just once we’ve reached the goal. This means simply that we are able to expand on our sustainability agenda.”

“We are preserving forest and working with communities hand-in-hand. We work with NGOs on a daily basis who tell us (with a couple of exceptions) we are doing the right thing, and saying so publicly,” says Wiener.

The journey towards the equivalent of the Round Table on Sustainable Palm Oil (RSPO)8 is something the company has taken bold steps towards, but it needs to take the rest of the industry with it. Having cleaned up the legacy of the previous management, the next stage, he concludes, is to support the smallholders in the international market and “ensure the whole industry comes together and signs up to mandatory standards”.

Sources

1 See https://bit.ly/32dQyPz at mightyearth.org

2 See https://bit.ly/2FLqdB5 at mightyearth.org

3 See https://bit.ly/31iTGuy at corrie-maccoll.com

4 See https://bit.ly/2CNd0GF at corrie-maccoll.com

5 See https://bit.ly/3l5XrLK at icmagroup.org

6 See https://bit.ly/3j2u8I8 at ecovadis.com

7 See https://bit.ly/3l2IPMV at halyconagri.com

8 See https://bit.ly/3iZy4cw at rspo.org

Go to Corporate Bank EXPLORE MORE

Find out more about products and services

Go to Corporate Bank Go to Corporate BankSubscribe Subscribe to our magazine

flow magazine is published annually and can be read online and delivered to your door in print

Stay up-to-date with

Sign-up flow newsbites

Choose your preferred banking topics and we will send you updated emails based on your selection

Sign-up Sign-upYou might be interested in

Trade finance and lending

Journey into simplicity Journey into simplicity

How will India’s meet its US$5trn GDP target in the next five years? And what role will financiers, government reform and technology have in making this happen? Clarissa Dann reports on GTR’s one-day conference in Mumbai

Trade finance and lending

After the perfect storm After the perfect storm

flow reports on how a seven-year reserve-based lending solution positioned oil producer Noreco for growth in a two-year turnaround journey

Trade finance and lending

Deals on the ground Deals on the ground

From proprietary copper extraction technology to lighting up Egypt, flow takes a closer look at four of the Deutsche Bank deals that scooped best deal in the TFR Deals of 2016 awards.